The WILD IV (Wheel Impact Load Detector) represents the latest innovation in rail safety technology from L.B. Foster, designed to monitor and mitigate wheel impact forces in rail systems.

This hardened electronic wild system accurately measures and collects data of loads and impacts translated onto the rail through precision rail-mounted strain gauges and front-end processors.

The WILD IV delivers comprehensive rail wheel contact load monitoring through precision load cell systems, providing real-time wheel impact assessment, rail load monitoring, and comprehensive train wheel analysis for freight, transit, and industrial railway operations.

As part of L.B. Foster's Total Track Monitoring suite, the WILD IV system combines advanced rail detector capabilities with intelligent impact detection to ensure optimal wheel and track system performance whilst maintaining the highest safety standards. WILD systems evaluate millions of wheels per day throughout the international rail industry with proven accuracy and reliability.

Ordering and More Information

Learn more about our Wheel Impact Load Detector technology, complete our short contact form to connect with our expert team.

Key Features of the WILD System

Precision Monitoring: The WILD IV uses precision strain gauges to measure wheel impacts, imbalances, weight, and speed as they pass the detector. This ensures accurate and reliable data collection essential for maintaining rail integrity and wheel impact monitoring.

Comprehensive Data Reporting: Capable of reporting train weight and speed, wheel impacts, lateral forces, and truck hunting, the WILD IV provides detailed insights into rail conditions through advanced rail wheel sensor arrays and impact detector systems.

Real-Time Alerts & Management: The integrated Wheel Data Management System (WDMS) allows users to configure and manage alarms, designate personnel to receive real-time alerts, and review the health status of the system. This immediate feedback helps in preventing infrastructure damage and reducing train delays.

Advanced Diagnostics: Equipped with self-diagnostic features, the WILD IV ensures that any issues within the system are promptly identified and addressed, maintaining optimal performance through continuous wild monitor capabilities and rail track monitoring system integration.

Essential Performance Data: The data collected is an essential component of any performance-based wheel management program. The WILD continually monitors rail vehicle health to ensure safe and productive train operations, providing wild rails values tracking and comprehensive rail monitoring capabilities.

WILD IV Brochure

Why WILD Systems Are Critical for Railway Safety

Preventing Costly Derailments

The WILD system has proven its effectiveness in preventing costly derailments and protecting railway infrastructure investments across freight operations worldwide.

L.B. Foster technician installing WILD IV strain gauge sensors and circuit boards on railway track infrastructure. The precise installation of these monitoring devices enables real-time detection of wheel impacts, train weights, and potential safety hazards to improve railway operations and maintenance scheduling.

L.B. Foster technician installing WILD IV strain gauge sensors and circuit boards on railway track infrastructure. The precise installation of these monitoring devices enables real-time detection of wheel impacts, train weights, and potential safety hazards to improve railway operations and maintenance scheduling.

Infrastructure Protection

Rail impact forces from defective wheels cause substantial damage to vehicles, cargo, and track infrastructure. The WILD detector identifies these hazardous conditions before they escalate, protecting your entire railway network investment.

Operational Efficiency

Rather than time-based maintenance schedules, wheel management systems enable condition-based maintenance. WILD monitoring allows trains to be left in service longer by identifying defects as soon as they appear.

A report published in 2019 by the FRA showed that by implementing WILD IVs and utilising them to inform wheel maintenance, a major U.S. Transit agency extended the lifespan of its wheelsets by over 20% in a single year, with an estimated savings of $1.6M annually. WILD IV Wheel Impact Load Detector Brochure, L.B. Foster

Safety Compliance

WILD products form the foundation of AAR WABL Committee requirements for wheel defect identification and removal, ensuring full regulatory compliance whilst maintaining operational safety standards. The Wheels, Axles, Bearings, & Lubrication Committee (WABL) establishes standards to certify and monitor new rail equipment, and WILD products satisfy all WABL requirements, authorising railroads to pass the cost of wheel replacement back to car owners.

Applications Across Railway Industries

Freight Operations

The WILD system is ideal for detecting high-impact forces caused by heavy loads, ensuring the longevity of rail infrastructure and preventing derailments. WILD systems excel in freight environments where heavy rail load conditions and wheel flat detection are critical. The system's defect detector railroad capabilities identify wheel defects including shelling, spalling, fractures, and broken rims before they compromise safety.

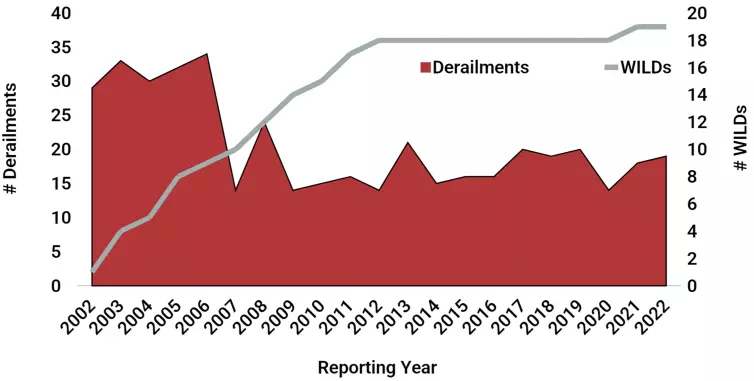

FRA Reportable Wheel & Load Related Derailments

Data provided by the FRA Office of Safety Analysis shows that adoption of WILD products on a class I freight agency’s network correlated with a decrease in wheel and weight related derailments from 13.5 to 5.2 annually.

Data provided by the FRA Office of Safety Analysis shows that adoption of WILD products on a class I freight agency’s network correlated with a decrease in wheel and weight related derailments from 13.5 to 5.2 annually.

Transit Networks

The WILD enhances passenger comfort by identifying and addressing wheel defects that cause noise and vibration. For passenger railways, WILD monitors provide targeted wheel maintenance scheduling as a critical component of optimised wheel maintenance. As opposed to wheel maintenance based on time or distance intervals, defects can be identified as soon as they appear, allowing trains to be left in service longer.

Close-up view of L.B. Foster Salient Systems WILD IV strain gauge sensor mounted on railway infrastructure. This precision monitoring device continuously measures wheel impacts and loads as trains pass, providing critical data for railway safety and maintenance programmes.

Close-up view of L.B. Foster Salient Systems WILD IV strain gauge sensor mounted on railway infrastructure. This precision monitoring device continuously measures wheel impacts and loads as trains pass, providing critical data for railway safety and maintenance programmes.

Another benefit of targeted wheel defect removal is its effect on noise & vibration. One of the most common complaints of passenger rail riders is a loud, bumpy ride, often caused by poor wheel condition. L.B. Foster is currently partnered with a major Transit agency to quantify the effects of optimised wheel maintenance on noise & vibration, providing better insight into when a wheel creates issues for riders and what sort of improvement in ride quality can be expected.

Industrial Railways

Industrial and mining operations benefit from WILD track monitoring systems that provide critical data for optimising wheelset maintenance and preventing costly penalties associated with overload and imbalance at transfer points. The system prevents expensive penalties at interchange points through precise overload detection and wheel flaw detect capabilities.

Data provided by the FRA Office of Safety Analysis showed that by implementing WILDs and utilizing them to inform wheel maintenance on a class I freight agency's network, correlated with a decrease in wheel and weight related derailments from 13.5 to 5.2 annually, saving the railroad over $1.5M each year. WILD IV Wheel Impact Load Detector Brochure, L.B. Foster

Advanced Monitoring Capabilities

Real-Time Health Status: Each WILD system provides comprehensive site health monitoring with graphical interfaces showing the status of all major components. Strain gauges, FEPs, tag readers, and bungalow equipment are continuously monitored with built-in diagnostics and troubleshooting recommendations.

Multi-Parameter Analysis: The system simultaneously monitors wheel impact, lateral forces, truck hunting, train speed, direction, and rail temperature whilst providing automatic car counting and identification capabilities.

Customisable Alert Systems: Threshold configuration allows users to set multiple alarm levels for each parameter, with FTP or email notifications sent to designated personnel when alarms are generated.

Contact Our Technical Team

For detailed technical specifications, installation requirements, or to discuss how WILD systems can enhance your railway operations, contact our experienced technical sales engineers. We'll provide comprehensive analysis of your specific requirements and recommend the optimal WILD configuration for your network.

Ordering and More Information

Learn more about our Wheel Impact Load Detector technology, complete our short contact form to connect with our expert team.

Contact L.B. Foster Regional Representatives