Rockfall monitoring is a revolutionary safety system that uses advanced LiDAR technology to detect rocks and hazardous obstacles on railway tracks. Unlike traditional rock fall slide fences, our rockfall monitoring system provides direct track monitoring with superior accuracy and reliability.

Our cutting-edge system uses high-resolution LiDAR rail technology to provide continuous, real-time monitoring and alerts, safeguarding both the right of way and rolling stock. This advanced rockfall solution eliminates the high false alarm rates and missed detections associated with conventional slide fences.

Rockfall hazard on railway track - A large boulder blocks the railway line beneath towering rock faces, demonstrating the critical safety risks that advanced LiDAR rockfall monitoring systems are designed to detect and prevent.

Rockfall hazard on railway track - A large boulder blocks the railway line beneath towering rock faces, demonstrating the critical safety risks that advanced LiDAR rockfall monitoring systems are designed to detect and prevent.

Rockfall monitoring is part of L.B. Foster's comprehensive track monitoring systems portfolio, offering proven rockfall detection services for railway operators worldwide.

Rockfall Monitoring Resources

How Does Rockfall Monitoring Work?

LiDAR (Light Detection and Ranging) technology forms the foundation of our system. This advanced remote sensing method uses laser pulses to measure distances and create high-resolution maps of the railway environment.

LiDAR sensors are strategically positioned approximately 90 feet apart along the track, providing overlapping and redundant scan coverage. This LiDAR obstacle detection system continuously monitors a detection zone, typically 6 feet from the track center in either direction.

Ordering and More Information

Learn more about Rockfall Monitoring by L.B. Foster, complete our short contact form to connect with our expert team.

When rockfall or debris enters the monitored zone, the system immediately triggers alerts to rail operators about potential hazards. Advanced algorithms distinguish between genuine rockfall events and transient objects like wildlife, significantly reducing false alarms compared to traditional rockfall fence systems.

This real-time rockslide monitoring capability eliminates the need for dangerous manual inspections, repairs and provides automated hazard detection and response for enhanced rock fall protection. Additionally, Rockfall Monitoring automatically resets once a hazardous obstacle is removed from the detection area, saving time and money compared to the manual resets needed for a rockfall fence system.

Rockfall Monitoring by L.B. Foster has been proven in the toughest conditions to reliably detect obstacles and alert rail traffic of potential obstructions. Technical Specifications and Performance Data

Key Features and Benefits

Direct Track Monitoring with 100% Detection Rate

Precise Detection: Accurately determines rock size and position for effective monitoring

Real-Time Alerts: Instantly notifies rail operators of hazardous rockfall conditions with visual confirmation through integrated camera systems

Proven Performance: 100% detection rate for valid rockfall events compared to just 33% detection rate of traditional slide fences

L.B. Foster's advanced LiDAR rockfall monitoring system installed along a railway cutting through rocky terrain, providing continuous 24/7 surveillance of the track area to detect falling rocks and debris before they can obstruct train operations.

L.B. Foster's advanced LiDAR rockfall monitoring system installed along a railway cutting through rocky terrain, providing continuous 24/7 surveillance of the track area to detect falling rocks and debris before they can obstruct train operations.

Advanced Technology and Safety

Continuous Monitoring: 24/7 operation with advanced LiDAR fall detection algorithms

Sensor Redundancy: Safety-critical design with full sensor redundancy for reliable rockfall monitoring

Advanced Algorithms: Sophisticated rockfall software eliminates false alarms from environmental conditions and wildlife

Automatic Responses: Controls nearby signals, alerts maintenance crews, and initiates customer responses upon detecting rock fall events

System Integration and Reliability

Relay Outputs: Simplified signal integration with existing rail track monitoring systems

Email and Web Portal Alarms: Real time alerts to need to know users that detail an event

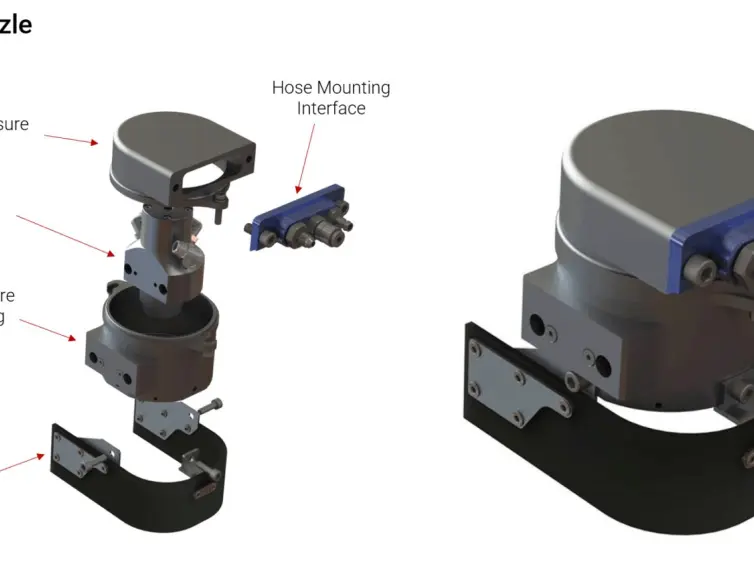

Ruggedised Housing: Durable LiDAR housing designed for harsh railway environments

Camera Integration: PTZ camera system captures images of events for visual confirmation

Superior Power Architecture: Reliable DC power system ensuring continuous operation with easy battery backup options

Superior to Traditional Rockfall Fences

Traditional rockfall fences suffer from significant limitations that compromise railway safety and operational efficiency. Slide fences typically experience:

96% false alarm rate leading to unnecessary maintenance callouts

Missed detections of genuine rockfall events (2 missed missed detections in trials)

High maintenance costs averaging $3,500 per callout

Extended slow order periods causing operational delays

Our system addresses these critical shortcomings through direct track monitoring rather than indirect fence-based detection. Real-world head-to-head trial data from British Columbia demonstrates:

100% detection rate for valid rockfall events

Increased network velocity on subdivision allowing 2-3 more trains per day without slide fence delays

Dramatic cost savings with only 2 scheduled callouts versus 85 unscheduled callouts for traditional fences

Superior rock fall protection through continuous LiDAR monitoring

During head-to-head trials in British Columbia, L.B. Foster's rockfall monitoring system successfully detected all three valid rockfall events. In contrast, the traditional slide fence system missed two of the three events. Case Study: Safer and More Cost-Effective than Traditional Slide Fences

System Specifications

Installation and Coverage

Sensor Spacing: LiDAR units positioned no more than 90 feet apart for redundant coverage

Detection Zone: Typically 6 feet from track center in either direction, triggering alarms for rockfall within this critical area

Mounting Height: LiDAR scanners mounted 24 inches above top of rail for optimal detection

Communication Range: Control panel within 3,000 feet of LiDAR equipment

Power and Performance

Unlike battery-powered wireless systems that require regular maintenance and suffer from power degradation, our system uses a robust DC power architecture that delivers continuous high-power operation with 25W per LiDAR unit, enabling advanced scanning capabilities and sophisticated detection algorithms. This eliminates costly battery replacement cycles whilst maintaining consistent detection accuracy 24/7 without performance degradation.

Control System

Advanced Processing: On-site safety-critical processor analyses incoming LiDAR data and controls track condition indicators

Camera Integration: PTZ camera system captures images of alarm events, providing visual confirmation of hazardous conditions

Signal Integration: Housed in signal enclosure with relay outputs for existing railway systems

Data Management and Performance

Our rockfall monitoring system features sophisticated rockfall software for comprehensive data management, capturing and storing detailed event data from incidents. This intelligence helps build detailed profiles of rockfall events, allowing operators to identify patterns and take preventative actions.

The integrated software provides operators with real-time dashboards, alarm logs, and comprehensive reporting capabilities, including:

Event Analysis: Detailed profiles of frequency and severity

Predictive Maintenance: Identification of patterns to prevent future rockslide events

Operational Insights: Data-driven decisions for rockfall mitigation strategies

Historical Tracking: Long-term monitoring of activity patterns

Proven Track Record

L.B. Foster's system has been successfully deployed across diverse railway environments, from the Pacific Northwest to New Mexico and British Columbia, with multiple successful installations, harsh environment testing, head-to-head trials demonstrating superiority over traditional slide fences, and customer acceptance with integration into permanent railway operations.

The system's ability to provide reliable rockfall detection whilst reducing operational costs makes it the preferred choice for railway operators seeking advanced rock fall protection solutions.

L.B. Foster's LiDAR rockfall monitoring system deployed in mountainous terrain, showing the ruggedised housing and DC power infrastructure that enables continuous 24/7 operation in harsh environments where rockfall poses significant risks to railway operations.

L.B. Foster's LiDAR rockfall monitoring system deployed in mountainous terrain, showing the ruggedised housing and DC power infrastructure that enables continuous 24/7 operation in harsh environments where rockfall poses significant risks to railway operations.

Ordering and More Information

Learn more about Rockfall Monitoring by L.B. Foster, complete our short contact form to connect with our expert team.

Contact L.B. Foster Regional Representatives